A Package Water Treatment Plant is a fully assembled, skid-mounted water treatment system that provides a turnkey solution for municipal, industrial, and commercial water needs. Pre-tested and modular, it enables rapid on-site deployment with configurable treatment trains (filtration, RO/UF, disinfection) for reliable water quality and low operating costs.

| Model | Water purification capacity (m3/h) | Influent turbidity (NTU) | Effluent turbidity (NTU) | Operating weight (T) |

|---|---|---|---|---|

| WLYT-10 | 10 | ≤1500 | ≤1 | 20 |

| WLYT-20 | 20 | 37 | ||

| WLYT-30 | 30 | 58 | ||

| WLYT-40 | 40 | 78 | ||

| WLYT-50 | 50 | 90 | ||

| WLYT-60 | 60 | 105 | ||

| WLYT-100 | 100 | 160 | ||

| WLYT-125 | 125 | 200 | ||

| WLYT-150 | 150 | 230 | ||

| WLYT-200 | 200 | 340 |

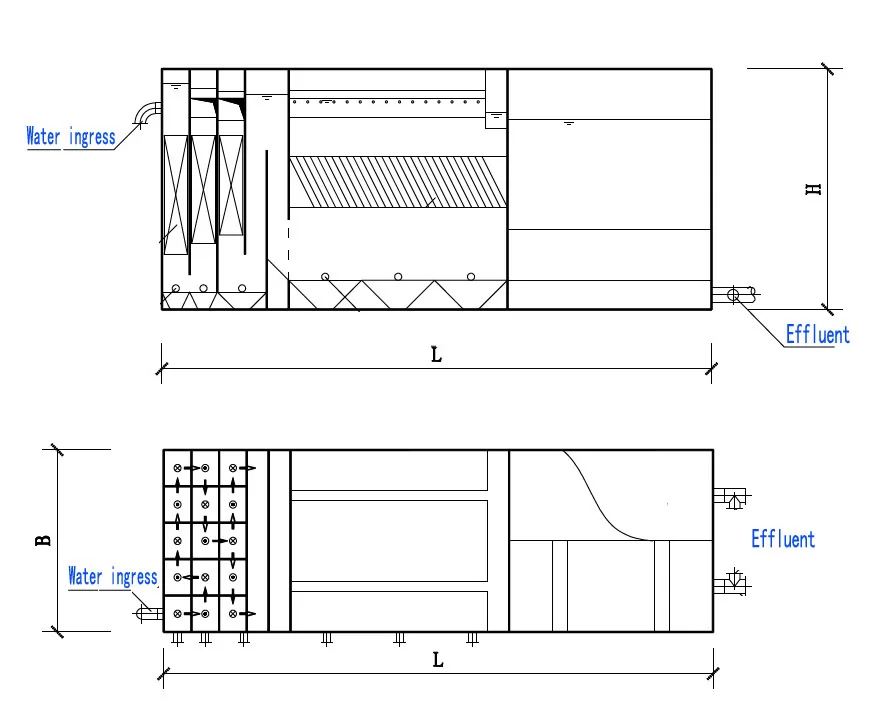

| Model | L×B×H (Length×Width×Height) | Inlet pipe | Clean water pipe | Sludge discharge pipe | Backflush pipe |

|---|---|---|---|---|---|

| WLYT-10 | 2500×1500×3700 | 65 | 65 | 100 | 150 |

| WLYT-20 | 3300×2000×4000 | 80 | 80 | 150 | 2×100 |

| WLYT-30 | 4000×2500×4300 | 100 | 100 | 150 | 2×150 |

| WLYT-40 | 4550×2800×4200 | 150 | 150 | 200 | 2×150 |

| WLYT-50 | 5900×2800×4500 | 150 | 150 | 200 | 2×200 |

| WLYT-60 | 5550×3500×4500 | 150 | 150 | 2×150 | 2×200 |

| WLYT-100 | 9850×3550×4500 | 200 | 2×200 | 2×150 | 2×200 |

| WLYT-125 | 10500×4050×4500 | 200 | 2×200 | 2×200 | 2×250 |

| WLYT-150 | 11100×4500×4500 | 250 | 2×250 | 2×200 | 2×300 |

| WLYT-200 | 11700×6000×4500 | 300 | 2×300 | 2×200 | 2×300 |

| Common faults | Causes | Troubleshooting | Notes |

|---|---|---|---|

| Small flocs | Insufficient coagulant dosage. | Increase dosage appropriately. | |

| Loose, floating flocs | Excessive coagulant dosage. | Reduce dosage appropriately. | |

| Rising flocs, high turbidity in clarified water | Too much sludge or excessive influent flow. | Remove sludge promptly or reduce flow rate. | If raw water turbidity exceeds 500 NTU, remove sludge frequently. |

| The influent and alum dosage are appropriate, but the effluent is still unclear. | Sludge buildup in the inclined tube or excessive influent flow. | Clean the inclined tube or add more filter media. | |

| Clarification is normal, but the filtered water quality is poor. | Filter media saturated with contaminants. | Stop operation and backwash immediately. |