This Filter Block represents a novel and superior filter component capable of simultaneously performing the functions of filtration, backwash water distribution, and air distribution. The Block incorporates an automatic compensation feature to ensure a more uniform distribution of both water and air.

The Filter Block employs a dual-layer water and air distribution system, consisting of a:

Key Technical Feature:Dual-Layer Distribution System

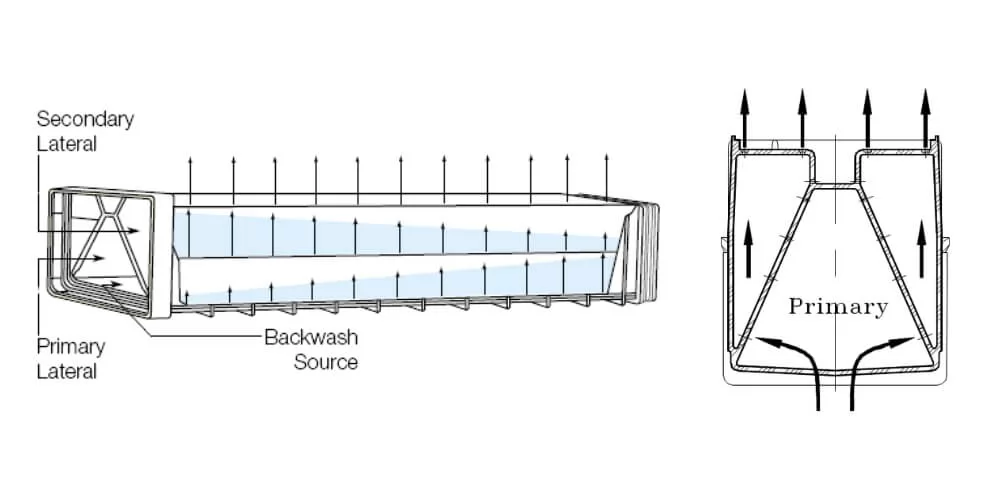

The Filter Block employs a dual-layer water and air distribution system, consisting of a:

Primary Distribution Chamber

Secondary Compensation Chamber

This Filter Blocks are used inside filter beds, serving as filter media support and distributing water and air. Filter bricks are a new and excellent filter bed component, capable of simultaneously performing filtration, backwashing water distribution, and air distribution. They also feature an automatic compensation function for more uniform water and air distribution.

How it Works: The backwash water, after passing through the primary distribution chamber, enters the secondary compensation chamber. Here, based on pressure differentials, an inverse compensation effect occurs. This mechanism ensures that the final, overall backwash water and air pressure is highly uniform across the entire filtration area of the filter basin.

The internal design of the secondary distribution chamber guarantees that the backwash water and air are evenly distributed at every diffusion orifice across the entire air-water backwash system of the filter.

This design achieves simultaneous, uniform air and water distribution within a single block, eliminating any distribution blind spots and ensuring a dead-zone-free backwash performance across the entire filter bed.

The secondary distribution design ensures the uniform distribution of water and air at every diffusion orifice along the longer length of the filter block.

During backwashing, the backwash water enters the filter block from the primary distribution chamber. Because more water and air escape through the orifices furthest from the backwash inlet, the primary chamber's water and air distribution becomes uneven.

The imbalanced flow from the primary distribution chamber generates a reverse flow in the secondary compensation chamber, which creates a compensation effect that ultimately results in uniform overall pressure along the entire length of the filter block.

This mechanism provides highly uniform, stable backwash water with no dead zones (or blind spots) to the filter bed, thereby improving backwash efficiency and extending the filter run cycle.

The gas flowing through the filter block can create a low-pressure zone within the block, leading to water deficiency (or dehydration) at certain orifices, or even resulting in a reverse water flow.

The filter block incorporates a return channel (or reflux trough) design to ensure a stable and continuous water flow can exit from the upper orifices. This return channel is designed so that the water flow returning to the filter block can compensate for the low-pressure areas. Furthermore, the top of the primary air distribution orifices of the filter block is equipped with balancing holes, which can similarly compensate for the low-pressure zones.

Consequently, the performance of the filter block is significantly improved, thereby achieving better treatment results.

Traditional water and air distribution systems rely on fluid reflection, which results in backwash blind spots above the distribution system. This means that the backwash air and water cannot effectively clean the filter media.

In long-term operation, a large amount of sludge will accumulate in the support layer/filter media, increasing the head loss, shortening the filter run cycle, and posing a risk of support layer disturbance.

The filter blocks are characterized by being spaced closely apart from one another and not obstructing the orifices, thereby achieving a uniform distribution of air and backwash water without blind spots. The goal is to ensure the unobstructed operation of the filtration system, leading to better cleaning results for the filter media.

The filter block is a type of block with secondary water and air distribution, and its functions are:

A. To provide a solid structure for supporting gravel and sand media.

B. To prevent gravel from entering the distribution system.

C. To minimize damage to internal filter basin components caused by hydraulic shock.

D. To ensure smooth discharge of the filtered effluent from the filter basin.

E. To ensure uniform distribution of backwash air and water across the entire filter bed area, guaranteeing a level filter media surface after washing.

F. To isolate the backwash system from the biological reaction system, preventing biological clogging of the air and water distribution system.

The air and water distribution filter block is entirely made of HDPE (High-Density Polyethylene) material, possessing excellent structural strength and toughness, ensuring the filter block has a service life of no less than 30 years.

| No. | Item | Feature | Advantage |

|---|---|---|---|

| 1 | Filter Block Structure |

Dual-layer distribution system: Primary Distribution Chamber (Central Triangular Chamber) Secondary Compensation Chamber (Two Parallel Triangular Chambers on the Sides) |

Uniform backwash water intensity with no blind spots. |

| 2 | Filter Block Special Design |

Water return channel (Reflux Trough) on the upper part of the block Air baffle in the compensation chamber |

Controls the uniformity of backwash air intensity. |

| 3 | Filter Block Dimensions | W×L×H = 292×1000×330mm | Saves filter basin height, reducing civil engineering costs. |

| 4 | Filter Block Material | HDPE (High-Density Polyethylene) | Excellent corrosion resistance, aging resistance, and impact resistance. |