When planning to install a Package Wastewater Treatment Plant (PWTP), the first question on most decision-makers’ minds is always: “How much will it cost?” This is understandable, as the price can vary widely depending on capacity, technology, materials, and site conditions.

A PWTP is a pre-assembled, compact system designed for rapid deployment and reliable operation. Unlike traditional onsite wastewater plants that require extensive civil construction, packaged plants come as modular units—often containerized or skid-mounted—allowing for faster installation, lower civil work, and predictable performance.

Technically, a PWTP integrates multiple treatment stages, including:

Pre-treatment (screening and grit removal)

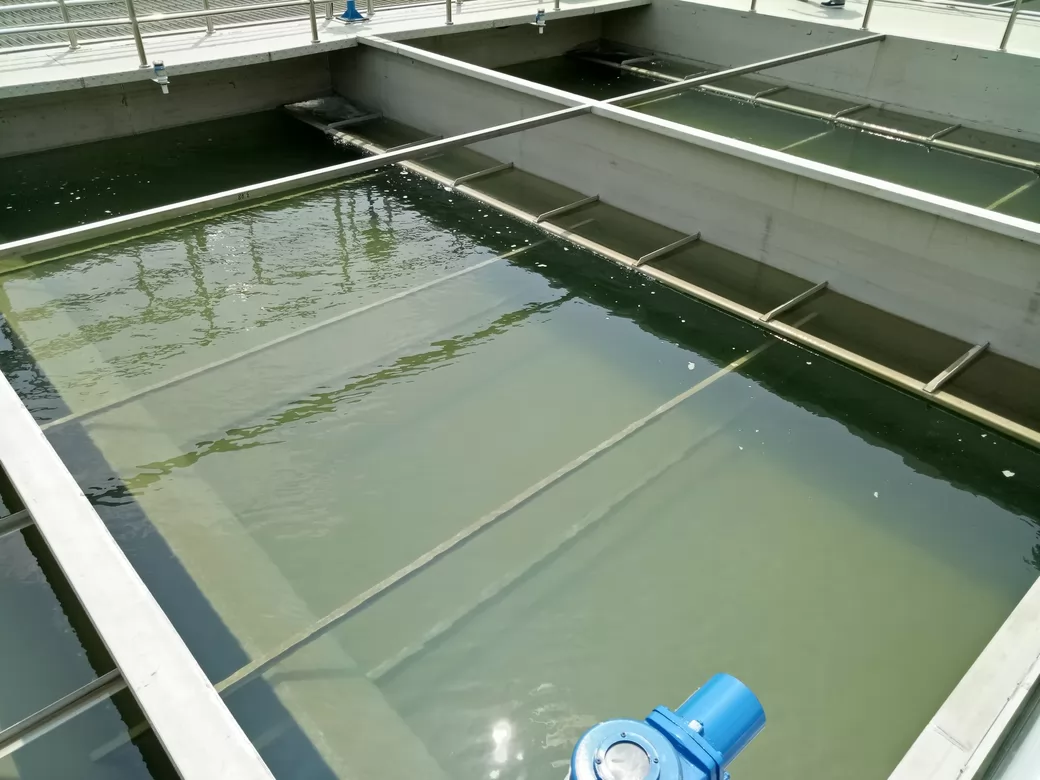

Primary sedimentation

Biological treatment (CAS, MBBR, MBR, or SBR technologies)

Tertiary treatment (for water reuse or higher discharge standards)

The combination of these processes ensures compliance with environmental regulations, protects public health, and often enables water reuse for irrigation or industrial purposes.

Understanding these technical components and how they influence cost is essential before comparing suppliers or requesting quotes. With that context, let’s look at the Quick Answer: Price Range for 2025, giving you a realistic baseline to budget your project.

_1763947726_WNo_1280d684.webp)

For a standard Package Wastewater Treatment Plant (PWTP), the price varies widely depending on capacity and technology. To give you a clearer picture, the following table summarizes the estimated costs for 2025, organized by daily treatment capacity.

Table Overview:

Capacity (m³/day): Daily flow the plant can handle.

Typical Price (USD): Estimated equipment cost range (excluding civil works and installation).

Application: Common use cases for each capacity range.

This table provides a realistic baseline for budgeting and comparing options before requesting a detailed quote.

Standard Package Wastewater Treatment Plants typically range from $20,000 to $400,000+ depending on capacity and technology.

| Capacity (m³/day) | Typical Price (USD) | Application |

|---|---|---|

| 10–50 | $20,000–$50,000 | Small hotels, resorts, camps |

| 50–200 | $50,000–$130,000 | Schools, small housing estates |

| 200–1000 | $130,000–$350,000 | Factories, hospitals, shopping malls |

| 1000+ | Contact for Quote | Large municipal or industrial plants |

Note: Prices are equipment only; civil works, installation, and shipping are additional.

The choice of technology significantly affects the cost of a Package Wastewater Treatment Plant. Different biological treatment methods provide varying effluent quality, footprint, energy consumption, and long-term maintenance requirements.

To help you understand the cost implications, the following table summarizes the relative costs, advantages, and limitations of commonly used treatment technologies for 2025:

Table Overview:

Technology: The main biological process used in the plant (e.g., CAS, MBBR, MBR, SBR).

Relative Cost: Approximate cost level compared to other technologies.

Pros: Key advantages, including performance and operational benefits.

Cons: Potential drawbacks or higher operational requirements.

Use this table as a reference to compare technologies and evaluate which option aligns best with your project requirements.

| Technology | Relative Cost | Pros | Cons |

|---|---|---|---|

| CAS (Activated Sludge) | $ (Low) | Reliable, proven | Large footprint, moderate effluent quality |

| MBBR | $$ (Medium) | Compact, handles shock loads | Requires bio-media, higher energy |

| MBR | $$$ (High) | High effluent quality, reuse possible | Expensive, membranes need replacement |

| SBR | $$ (Medium) | Flexible, batch operation | Requires automation |

Impact: Determines the required treatment process and level.

Impact: Affects durability, lifespan, and corrosion resistance.

Impact: Determines operational efficiency and maintenance costs.

Impact: Influences civil work, installation time, and total project cost.

Selecting the right Package Wastewater Treatment Plant (PWTP) is crucial for ensuring long-term reliability, compliance with discharge standards, and optimal operational efficiency. Here are some practical tips for beginners and decision-makers:

Daily Flow Rate: Know the average and peak m³/day to avoid under- or over-sizing.

Effluent Quality Standards: Decide if treated water is for discharge or reuse (irrigation, flushing, or industrial).

Wastewater Type: Domestic, industrial, or hospital wastewater has different treatment needs.

CAS (Conventional Activated Sludge): Reliable and low-cost, suitable for basic discharge.

MBBR (Moving Bed Biofilm Reactor): Compact, handles variable loads, moderate cost.

MBR (Membrane Bioreactor): Best effluent quality, ideal for water reuse, higher cost and maintenance.

SBR (Sequencing Batch Reactor): Flexible batch operation, requires automation.

Tip: Choose technology that balances effluent quality, footprint, and OPEX.

Carbon Steel (Coated): Standard choice, cost-effective, lifespan 10–15 years.

FRP (Fiberglass): Corrosion-resistant, moderate price.

Stainless Steel (304/316): Premium option, 20+ years lifespan, +30–50% cost.

Tip: Consider local water chemistry and environmental exposure when selecting materials.

Standard Systems: Local brand pumps and basic controls, lower upfront cost.

Premium Systems: PLCs (Siemens/Schneider), high-quality pumps (Grundfos/Ebara), remote monitoring modules.

Tip: For critical or large plants, investing in high-quality components reduces downtime and long-term OPEX.

Containerized / Packaged: Faster installation, minimal civil work, slightly higher equipment cost.

Integrated / Onsite Installation: Lower equipment cost, requires civil work for concrete tanks.

Tip: Evaluate site space, access, and construction capabilities.

Experience: Look for manufacturers with proven track records in PWTP projects of similar scale.

After-Sales Service: Installation guidance, commissioning, spare parts, and maintenance support are crucial.

Tip: Request references or case studies to ensure reliability.

Consider not only CAPEX but also OPEX: energy, chemicals, sludge disposal, membrane replacements.

Tip: A slightly higher initial investment may save significant operating costs over the plant’s lifecycle.

Obtaining an accurate quote for a Package Wastewater Treatment Plant (PWTP) is essential for budgeting, planning, and avoiding unexpected costs. The more detailed and precise your project information, the closer the quote will reflect the actual cost and scope of work. Here’s a step-by-step guide:

Type of wastewater: Domestic, industrial, or specialized (hospital, food processing, chemical).

Characteristics: COD, BOD, TSS, pH, and presence of hazardous substances.

Tip: Providing laboratory test results or historical data ensures a more accurate system design.

Average flow: Typical m³/day your plant needs to handle.

Peak flow: Maximum expected flow during the day.

Tip: Overlooking peak flow can result in undersized plants, while overestimating can increase costs unnecessarily.

Regulatory compliance: Local discharge standards for rivers, lakes, or municipal sewage systems.

Water reuse goals: Irrigation, flushing, or industrial reuse may require tertiary treatment.

Tip: Clearly defining discharge standards reduces ambiguity and prevents cost surprises.

Site type: Above-ground, underground, or confined space.

Accessibility: Roads, cranes, and lifting capacity for containerized units.

Tip: Detailed site information prevents additional installation costs due to unexpected obstacles.

Control level: Basic relay-based control or advanced PLC automation.

Pump and component brands: Local or premium brands.

Tip: Suppliers can provide more accurate quotes if they know your preferred automation level and component quality.

Operating hours: Continuous or intermittent operation.

Climate and environment: Temperature, humidity, corrosive atmosphere.

Future expansion: Possibility of increasing capacity later.

Investing in a Package Wastewater Treatment Plant (PWTP) is a strategic decision that balances initial capital expenditure (CAPEX) with long-term operational costs (OPEX). Choosing the right capacity, technology, materials, and installation type ensures compliance with environmental standards, reliable performance, and optimal cost efficiency over the system’s lifecycle.

At Weilai, we specialize in delivering customized, high-quality PWTP solutions for industrial, commercial, and municipal clients. Our systems are designed with robust engineering, energy efficiency, and long-term durability in mind, helping you achieve both regulatory compliance and operational savings.

Whether you are planning a small-scale plant for a hotel or a large municipal facility, our team provides expert guidance, transparent pricing, and full project support from design to commissioning.

Ready to get a tailored 2025 price quote for your project?

Contact Weilan today and receive a detailed proposal that meets your specific needs.

Your Name*

Your Email*