The Stainless Steel Filter Underdrain Block is an advanced, high-performance component designed for integration within the filter basin. It simultaneously fulfills the critical functions of filter media support and highly efficient water and air distribution during both filtration and backwash cycles.

This innovative system features a patented dual-layer distribution design with an automatic compensation function, ensuring unparalleled uniformity in water and air delivery.

The Stainless Steel Filter Underdrain Block is utilized inside the filter basin, serving the functions of filter media support and water/air distribution.

The Stainless Steel Filter Underdrain Block is a novel and superior filter component capable of simultaneously performing the functions of filtration, backwash water distribution, and air distribution. The Stainless Steel Filter Underdrain Block features an automatic compensation function to achieve more uniform water and air distribution performance.

The Stainless Steel Filter Underdrain Block uses a dual-layer water and air distribution system: a Primary Distribution Chamber and a Secondary Compensation Chamber. The backwash water, after passing through the primary distribution chamber, enters the secondary compensation chamber where an inverse compensation is generated based on pressure differentials. This mechanism ensures that the final, overall backwash water and air pressure is uniform across the entire filtration area of the filter basin.

The internal secondary water distribution design of the Stainless Steel Filter Underdrain Block ensures that the backwash water and gas are uniformly distributed at every diffusion orifice of the entire filter's backwash air-water distribution system. Uniform air and water distribution is achieved simultaneously within a single Stainless Steel Filter Underdrain Block, eliminating air and water distribution blind spots and resulting in dead-zone-free backwashing.

The secondary water and air distribution design ensures the uniform distribution of water and gas at every diffusion orifice along the longer length of the Stainless Steel Filter Underdrain Block.

In the Stainless Steel Filter Underdrain Block, backwash water and air flow from the inner primary distribution chamber into the outer secondary distribution chamber. Because more water and air escape through the orifices furthest from the backwash inlet, the primary distribution chamber's water and air distribution becomes uneven.

The imbalanced flow from the primary distribution chamber generates a reverse flow in the secondary distribution chamber, which creates a compensation effect, ultimately resulting in uniform overall pressure along the entire length of the Stainless Steel Filter Underdrain Block.

This provides highly uniform, stable backwash water with no blind spots for the filter bed backwashing, thereby improving backwash efficiency and extending the filter run cycle.

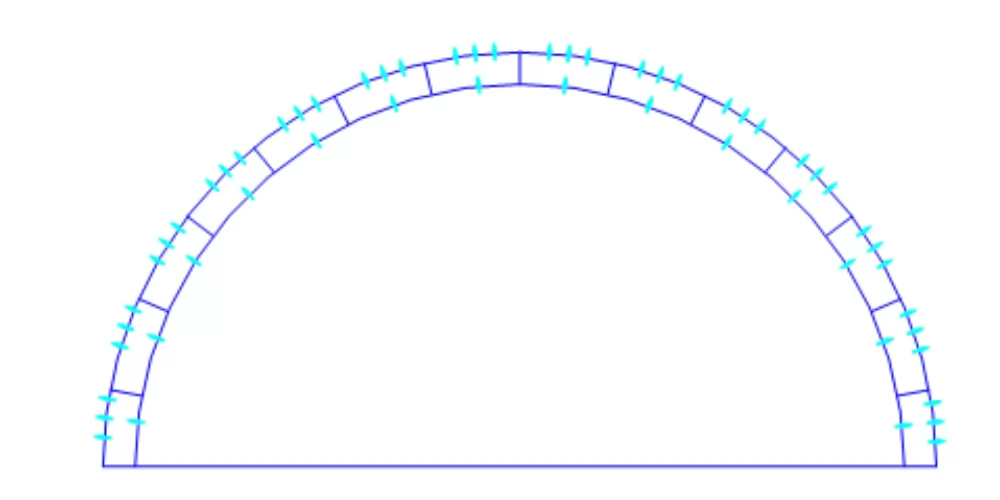

The Direct Filter Underdrain System is used to collect and distribute backwash water and air, and it includes the direct retention of the filter media. Various specifications of filter media can be laid directly on the upper part of the Direct Filter Underdrain System, eliminating the need for an additional support layer.

The Direct Filter Underdrain System products all utilize a V-shaped metal screen surface. The slot width can be designed and constructed according to different requirements to accommodate various types of media.

The Direct Filter Underdrain System features a large open area and minimal head loss, U-shaped channels, and V-shaped wire filter media support profiles, which provide surface slots suitable for any filter media specification.

Traditional water and air distribution systems rely on fluid reflection, resulting in backwash blind spots above the distribution system. This means that the backwash air and water cannot effectively clean the filter media.

In long-term operation, a large amount of sludge will accumulate in the support layer/filter media, increasing the head loss, shortening the filter run cycle, and posing a risk of support layer disturbance (or upset).

The Stainless Steel Direct Filter Underdrain System is characterized by the components being spaced closely apart from one another and not obstructing the orifices, thereby achieving a uniform, blind spot-free distribution of air and backwash water. The objective is the unobstructed operation of the filtration system, leading to better cleaning results for the filter media.