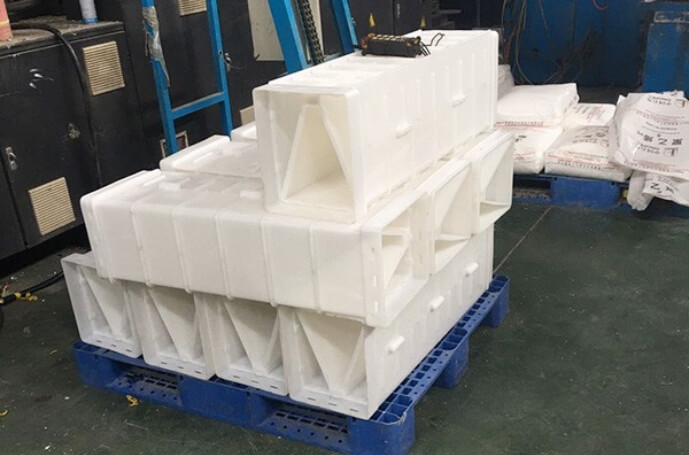

An Underdrain Filter is an essential component of water and wastewater filtration systems, designed to evenly distribute backwash water and support filter media for optimal performance. Engineered for uniform flow, high strength, and corrosion resistance, it ensures efficient filtration, prevents media loss, and extends system lifespan. Ideal for use in municipal, industrial, and environmental treatment applications, the underdrain filter enhances system reliability and simplifies maintenance.

Durable filter underdrain ensures uniform air-water distribution, longer filter runs, higher efficiency, and reduced operating costs.

Ensures consistent backwash flow for cleaner filters and longer operating cycles.

Made from corrosion-resistant HDPE for excellent durability and long service life.

Adaptable design fits new builds or retrofit projects with minimal installation effort.

Adjustable airflow reduces energy use and minimizes water waste during backwash.

Simple structure with no moving parts for stable, maintenance-free performance.

Maximizes water recovery and lowers operational costs over the system’s lifespan.

Weilan designs plans and drawings and supplies both standardized and bespoke water treatment systems, backed by over 200 completed projects.

Underdrains collects filtered water during filter operation and distributes air and water during the backwash cycle.

Excellent even distribution of air and water results in a longer pool.

The standard profile of B × L × H = 1000 × 300 × 330mm.

Providing cleaner filters means longer filter run time and higher water efficiency, more product water and Fewer wastes. This can reduce operating costs per gallon or liter of filtered water.

Made of HDPE for excellent strength and corrosion resistance. Flexible design, ideal for installations that require longer laterals.

It can be equipped with media holder, up to 14 inches (36 cm) of gravel media holder can be replaced, so that in less vertical space or longer air / water backwash time to achieve the same media depth.

Air flow adjustability allows for more control and saves energy and water.

Uniform air-water distribution, which produces less waste water and reduces the operating cost of the filter.

It is applicable to new or existing older filter installation, and can be applied to a variety of filter pool types, with convenient, stable and low cost installation.

Henan Weilan Water Treatment Technology Co., Ltd. (est. 2011) specializes in turnkey package

water treatment plants — modular, skid- and containerized systems pre-tested for rapid

on-site deployment.

Backed by an experienced R\&D and EPC team and ISO9001 quality management, Weilan

delivers engineered design, manufacturing, commissioning and lifecycle support for

municipal and industrial water projects.

Provide a total solution for safe drinking water and sewage treatment.

Full design services — standard modules and bespoke systems

Weilan’s Underdrain Filters are made of high-strength HDPE material, offering excellent corrosion resistance, structural stability, and long service life. This ensures reliable operation even under harsh water treatment conditions and minimizes maintenance requirements.

HDPE Underdrain Filters provide uniform air-water distribution, reduce clogging, and improve backwash efficiency. They extend filter runtime, save energy and water, and lower overall operational costs compared to traditional underdrain systems made from concrete or metal.

Yes. Weilan Water Treatment offers flexible underdrain designs that can be customized to fit various filter pool types and dimensions. Options include different lateral lengths, gravel media holders, and air flow adjustments to meet specific process and performance needs.

Yes. Weilan’s Underdrain Filters are ideal for both new installations and retrofitting existing filtration systems. Their modular design allows easy integration without extensive structural changes, making them a cost-effective upgrade solution for performance improvement.

Underdrain Filters require minimal maintenance due to their simple structure and durable materials. Regular inspections to ensure even airflow and occasional cleaning are typically sufficient to keep the system running efficiently for many years.

The article explains the operation of underdrain filters, covering filtration rates, backwashing steps, media settling, routine inspections, and basic troubleshooting tips.

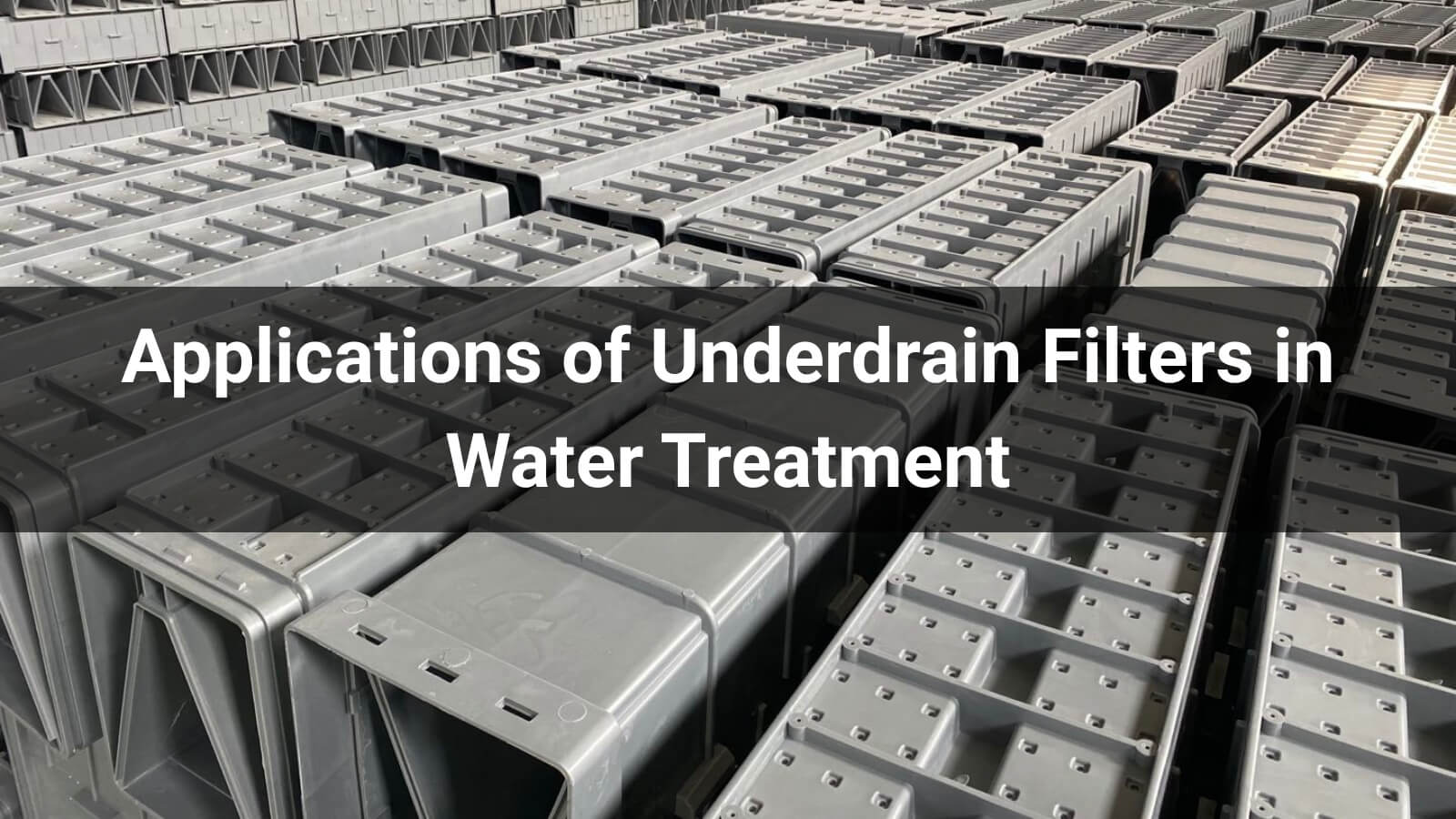

Discover the 5 most critical applications of underdrain filters in water treatment. From gravity filters to wastewater reuse, learn how these systems optimize filtration efficiency.

Compare HDPE vs. stainless steel underdrain filters in strength, durability, corrosion resistance, cost, and performance to choose the best option for your water treatment system.